Consultation Level

.

Nestlé Waters Europe - VERGEZE Factory – FRANCE 2021

Mapping the initial Sate

- Evaluate all the losses and identify the top priority losses.

- Build strong detailed Waterfall Plan based on the losses and define the glidepath targets.

- Conduct SWOT Analysis to assess the current status of TPM implementation across all pillars.

People Capability Building

- Perform self-assessment of the Autonomous Working Group & Planned Maintenance Working Group.

- Assess the current technical, operational and methodological skills level to identify all gaps versus the desired competency levels and develop the Competency Building Plan to close the gaps.

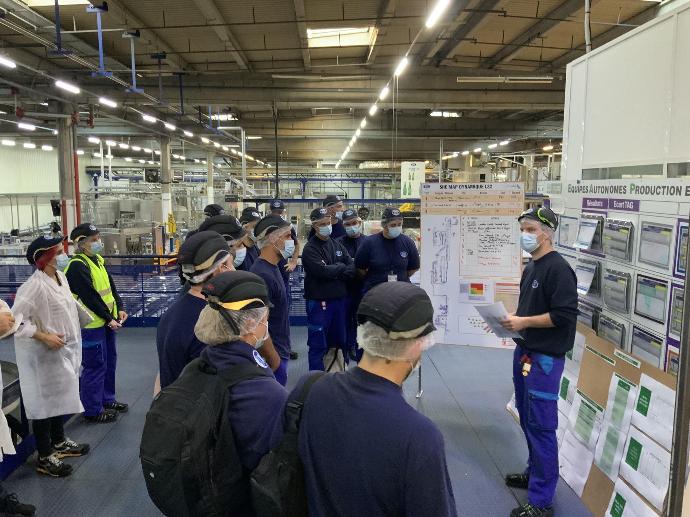

Workplace Transformation

- Performed Deep Cleaning to start Machine Basic Conditions Restoration.

- Review and assess the current standards and develop the best Cleaning, Inspection & Lubrication standards.

- Evaluate the center lining standards to correlate with the actual process failures and develop the best centerline conditions and apply Poka Yoke solutions when needed.

- Workplace transformation by applying 5S standards.

Breakthrough Results

- Reduce the Unplanned Stoppages to below 20% for lines 30 & 33 to complete TPM step 1

- Reduce the Unplanned Stoppages to below 15% for lines 31 & 32 to complete TPM step 2

- Reduce the change-over, start-up, shut-down time and cleaning time.

- Reduce the Material Losses MUV KPI by 10% vs pervious year.

Management Routines

- Apply Line centric organizational routines.

- Develop Plan Do Check Act/ Standardize Do Check Act Cycle Implementation across all levels.

- Strength the 7 Key Standard Routine Implementation & AWG/ MWG Routines as well as the Pillars Synchronization