Ledo Ice Cream Factory - Croatia 2022

5S Implementation & Workplace Transformation

1- 5S Committee forming & competency building.

2- Defining the Quarantine Area using the RED TAG.

3- Sort out old machine components & changeover parts.

4- Sort out spare parts storage room cleared from parts that were not used for long time and that are not in plan to use in next 18 months.

5- Define some improvement ideas to eliminate Ergonomic Risk for workers resulting from taking out products during the line stoppages.

6- Define new setup & optimize the physical efforts.

7- Accelerate the rollout to other areas.

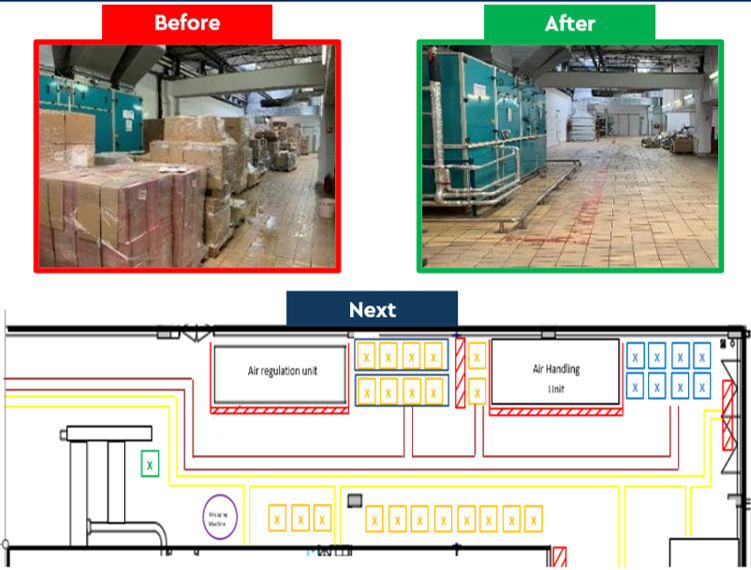

Production Supply Area – New Layout

- After clearing the area, we made the layout of how we want it to look

- All fire exits are accessible and without unnecessary items blocking them

- Air regulation units are accessible and there will be no pallets around them.

- 50 pallet spaces available in new layout.

Changeover Parts

- After clearing the area, we made the Spare parts storage room cleared from parts that were not used for long time and that are not in plan to use in next 18 months.

- Parts for same formats are stored together